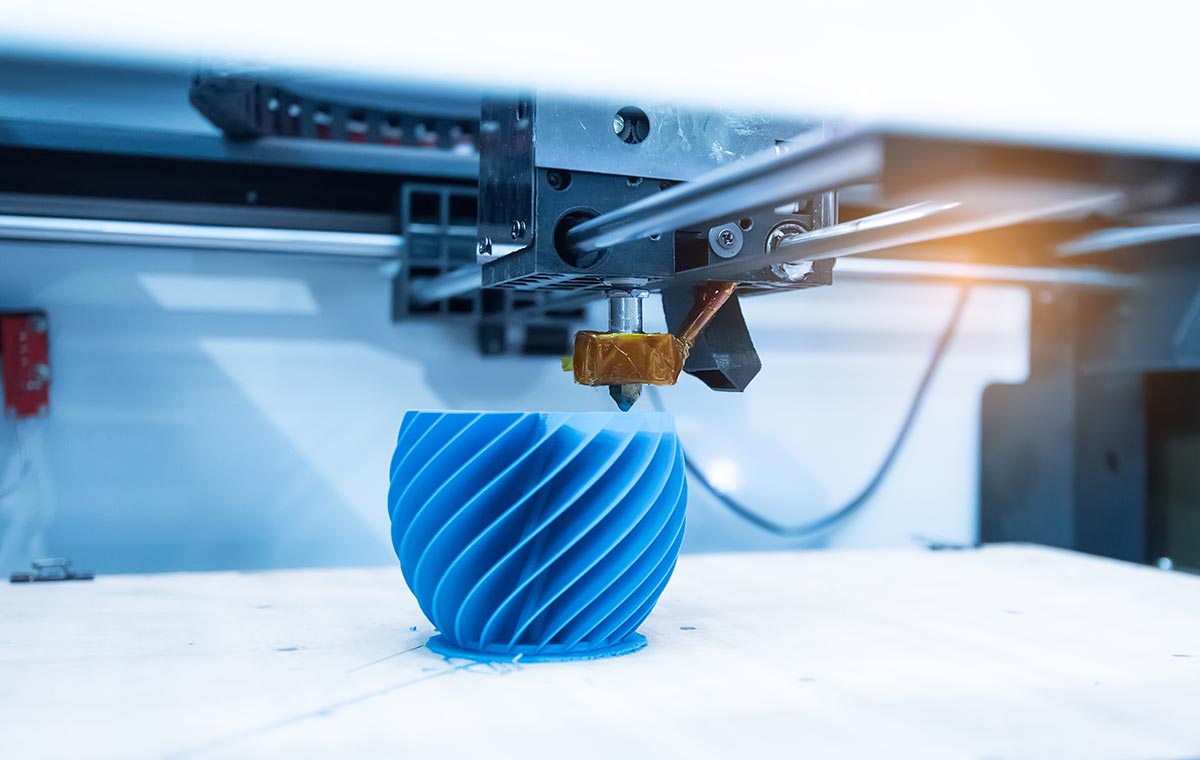

Which Industries Are Maximizing the Benefits of 3D Printing?

3D printing has been around for decades, but recent advancements in technology have made it more accessible and affordable than ever before. As a result, industries across the board are exploring the ways in which 3D printing can be utilized to streamline production and reduce costs. In this article, we’ll explore which industries are maximizing the benefits of 3D printing and hear from experts on the future of the technology.

One industry that has been significantly impacted by 3D printing is healthcare. With the ability to produce custom prosthetics, implants, and even human tissue, 3D printing is revolutionizing the way healthcare providers approach patient care. Additionally, 3D printing is being used to produce medical equipment and surgical tools, which can be tailored to the specific needs of individual patients.

According to Dr. Gordon Bundy, a plastic surgeon and associate professor of surgery at the University of Pennsylvania, “3D printing is providing us with new tools to solve old problems in healthcare. We can now produce implants and prosthetics that fit patients perfectly, which can lead to better outcomes and shorter recovery times.”

Manufacturing is another industry that has been significantly impacted by 3D printing. With the ability to produce complex parts and prototypes quickly and at a lower cost than traditional manufacturing methods, 3D printing is streamlining production processes across the board.

According to Howard Regens, a senior consultant at Wohlers Associates, a 3D printing consulting firm, “3D printing is disrupting traditional manufacturing by allowing companies to produce parts that would be impossible or extremely difficult to produce with traditional methods. This is leading to faster production times, reduced costs, and improved product quality.”

The aerospace and defense industries have also been early adopters of 3D printing technology. With the ability to produce lightweight, high-strength parts, 3D printing is allowing these industries to produce more efficient and effective aircraft and military equipment. Additionally, 3D printing is being used to produce parts for space exploration, including rocket components and even habitats for astronauts.

According to Scott Crump, the co-founder of Stratasys, a 3D printing company, “The aerospace and defense industries are seeing the benefits of 3D printing in terms of weight reduction, increased strength, and the ability to produce complex geometries. As the technology continues to improve, we can expect to see even more applications in these industries.”

The architecture and construction industries are also benefiting from 3D printing technology. With the ability to produce detailed models and prototypes quickly and at a lower cost than traditional methods, 3D printing is allowing architects and construction professionals to design and build more efficiently.

According to Dr. Alireza Farhangi, an assistant professor of construction engineering and management at the University of Colorado, “3D printing is providing architects and construction professionals with new tools to streamline the design and construction process. By producing accurate and detailed models quickly and at a lower cost, we can improve project outcomes and reduce waste.”

In summary, 3D printing technology has the potential to revolutionize a wide range of industries. From healthcare to manufacturing to aerospace and defense to architecture and construction, companies across the board are exploring the ways in which 3D printing can be utilized to streamline production, reduce costs, and improve outcomes. As technology continues to advance, we can expect to see even more innovative applications in these industries and beyond.